Steps Required To Make A Modern Road From Start To Finish

The oldest known roads are located in ancient Mesopotamia or modern-day Iraq. They were constructed of mud bricks that were set into place using bitumen, that sticky black substance we use in today’s asphalt.

In America, one of the first roads was Pennsylvania Avenue in Washington, and the first national road between states was built in 1811 and it flows through Illinois, Indiana, Maryland, Ohio, Pennsylvania, and West Virginia. The first asphalt road wasn’t built until 1870 in Newark, NJ. Now, the US has over 4 million miles of paved roads with approximately 31,000 road miles added each year and asphalt road construction is the most common road building process used today.

So you might be wondering how to make a road and what the road building process is like.

Here’s a guide to how roads are made and the various stages involved in road construction.

Stages Of The Road Building Process

Road technology has come a long way since the ancient days of mud bricks, but many of the elements of the road-building process are still the same. From demolition to the final masterpiece of a clean, smooth surface, roads are now made with a clear step-by-step process that ensures a long-lasting road that requires few repairs over the years. At Morgan Pavement, our professionals can handle each step of road construction and we provide comprehensive concrete asphalt paving services.

Regardless of whether you are constructing a large highway or a residential driveway, the road-building process is generally the same. Here’s how to build a road:

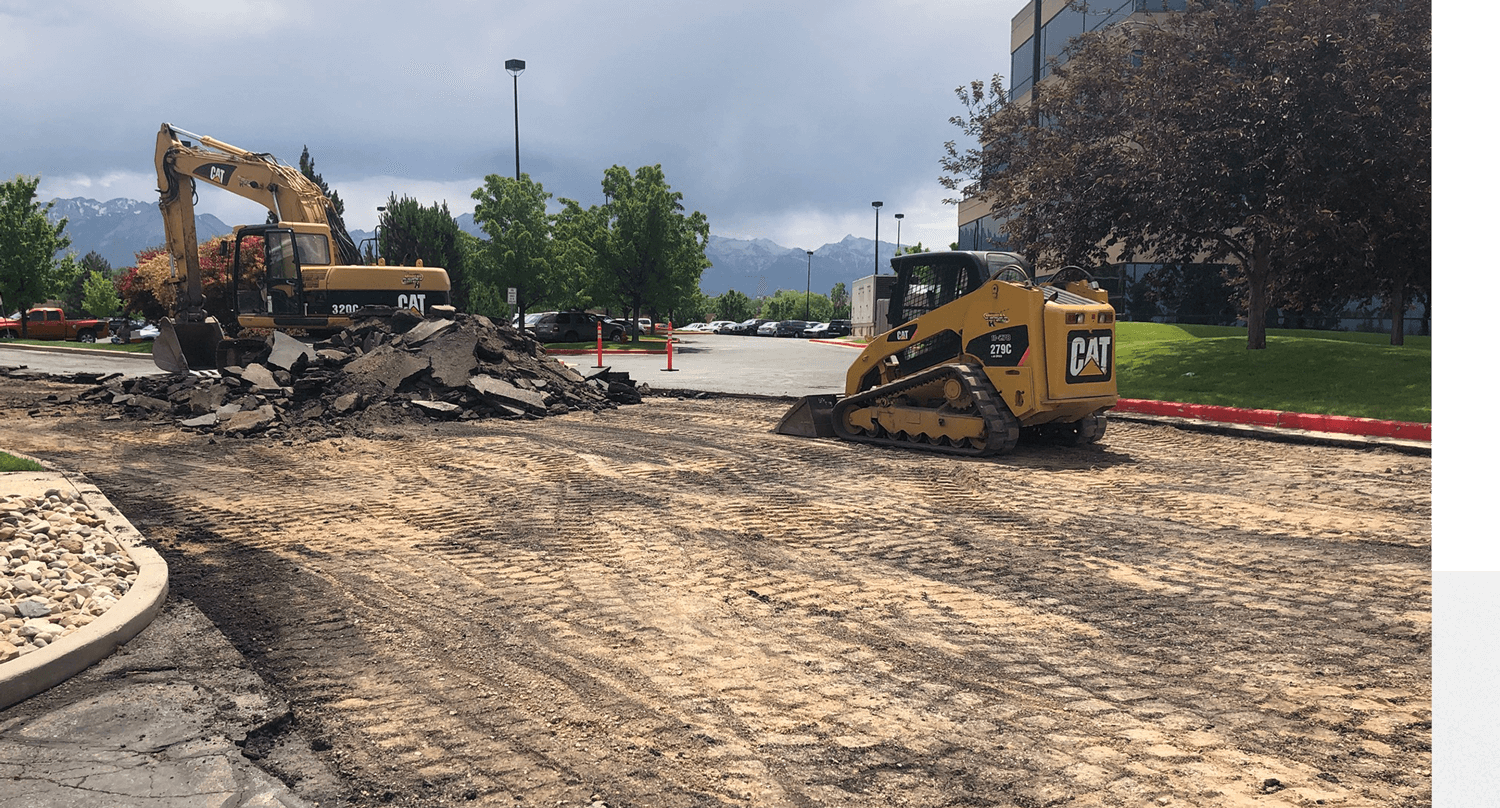

Prepare The Site – Clearing And Excavation

The first stage involved in road construction is to clear the land where the road is going to be built. This could involve demolition of any structures and removal of trees, vegetation, and any overburden.

Roads can sometimes take up to ten years to build. Depending on the location, the site may need extensive preparation work and analysis before work even begins. Some roads are cut through mountains and involve building a tunnel. Others may be cut into a mountainside and need to have control devices to prevent erosion, mudslides, and rockfalls. Additional structures such as drainage ditches, fences, or other items may need to be built.

Grading And Sloping

Next, the surface needs to be prepared. In some areas, dirt will need to be removed and other areas may need to be filled. Proper preparation is essential; otherwise, the final road may be subject to potholes or other failures.

The road needs to be sloped correctly to allow drainage and prevent standing water. In climates that fluctuate wildly between hot and cold temperatures, such as Utah, road construction must start with the right grade and sloping for safety reasons and to keep the road surface durable.

Sub-Bases for Asphalt Roads

Once the road is graded and sloped, your road construction team will bring in a sub-base. A sub-base is material that goes on top of the natural, native soil underlying the road.

Sub-base materials can be:

- Recycled concrete

- Granular fill

- Aggregate that has been manufactured

- Crushed concrete

- Other types of recycled materials, such as crushed bricks

A sub-base will be compacted to allow for proper drainage and will be composed of materials that will resist swelling and shrinkage during hot or cold temperatures. Depending on the load it’s expected to bear, it will be a specific depth.

After the sub-base is installed, it will be analyzed for any soft spots and those areas will be repaired before putting the next layer down.

Binder And Surface Course

Next, the binder layer will be installed. Those ancient people in Mesopotamia had it right from the very beginning. The most common binder layer is bitumen, which they used to keep the mud bricks from slipping and sliding.

Nowadays, this oily, sticky, natural substance is combined with aggregates to make a very stable and strong road. Perhaps the use of bitumen is why those ancient roads lasted so long. That’s why we can expect the roads we build today, with a bitumen binder layer to last as well.

The binder is the supportive structure of the road and is the primary foundation of a road that dictates how strong that road will be. Since it can be heated up to 240 degrees Fahrenheit before melting, bitumen is often used in extremely hot locales.

New Asphalt Installation

Next, a top layer of asphalt will be installed that gives a road its smooth surface. Bitumen mixed with particles and aggregates creates a liquid-like substance called asphalt that is easy to lay down and smooth out.

Asphalt is naturally black — a byproduct of oil production. When mixed with the particles it gives the roadway a nice, attractive appearance.

Joints And Transitions

Finally, a road will connect to other roads, driveways, entrances, and exits to parking lots. These transitions require special grading to ensure that drainage is still achieved and the transition is smooth for cars to drive over safely.

What Materials Are Used In Building Roads?

New technology is creating roads that are sustainable and better for the environment. For the most part, the materials used in road construction are soils and aggregates, asphalt, tar, and concrete.

Asphalt

Asphalt is a mixture of aggregates and a binder. Aggregates are usually processed mineral materials such as crushed rock, sand, gravel, slag, or recycled materials such as old asphalt, bricks, or concrete. The binder that glues the aggregates together is usually bitumen.

There are various grades of asphalt and the quality of the asphalt is dependent upon the quality of the aggregates that are used.

How Is Asphalt Made?

Asphalt has a very specific recipe, usually 95% aggregate and 5% binder. Asphalt is made by mixing these two ingredients. Most of the time, the binder is very thick and viscous. It needs to be thinned, either by heat, application of a thinning solvent, or emulsification in water before the aggregates are added.

Once the aggregates and the binder have been blended together, it needs to be heated to the correct temperature. Then, that temperature needs to be maintained during transport from the asphalt plant to the construction site.

Concrete

Concrete is made of water, cement, and aggregates. Concrete and cement are not interchangeable. Cement is a powdery binding agent, whereas concrete is the whole of cement with the aggregates added.

How Is Concrete Made?

Like asphalt, concrete has a specific recipe, usually 10-15% cement, 60-75% aggregates, and 15-20% water. Unlike asphalt, air may be entrained into the mixture which makes up about 5-8% of the mixture.

Concrete must be cured before it can be driven on since cement hardens over time. Curing involves hydrating the concrete for a specific period of time using machines or burlap cloths.

Getting A Bid On Road Construction From An Asphalt Paving Company

Morgan Pavement provides comprehensive asphalt and concrete services, including road construction for the Western United States. Located in Utah, our road construction services include both asphalt and concrete road construction for government contracts, residential driveways, HOA communities, and more.

To learn more about Morgan Pavement or to get a bid on road construction, including road resurfacing and repair, contact us for a bid.